Specifications

| Capacity | 500g - 2000g ClO2/h |

| Concentration of ClO₂ processed | upto 1g ClO2/l |

| Sodium chlorite | used 31% |

| Hydrochloric acid | used 30% |

| Process water pressure | 2-4 bar |

| Process water temperature | upto 35°C |

| Operating temperature | upto 35°C |

| Humidity | 90% |

| Net Weight Max | 150-200 kg |

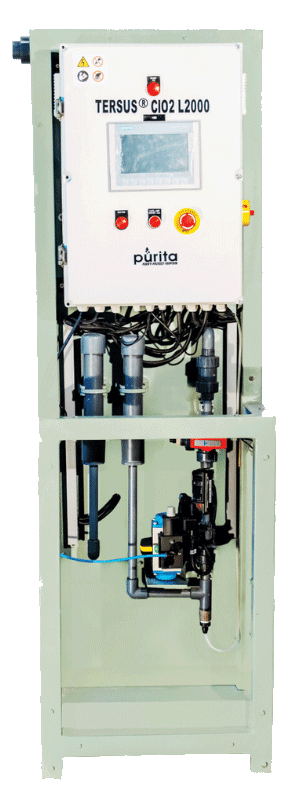

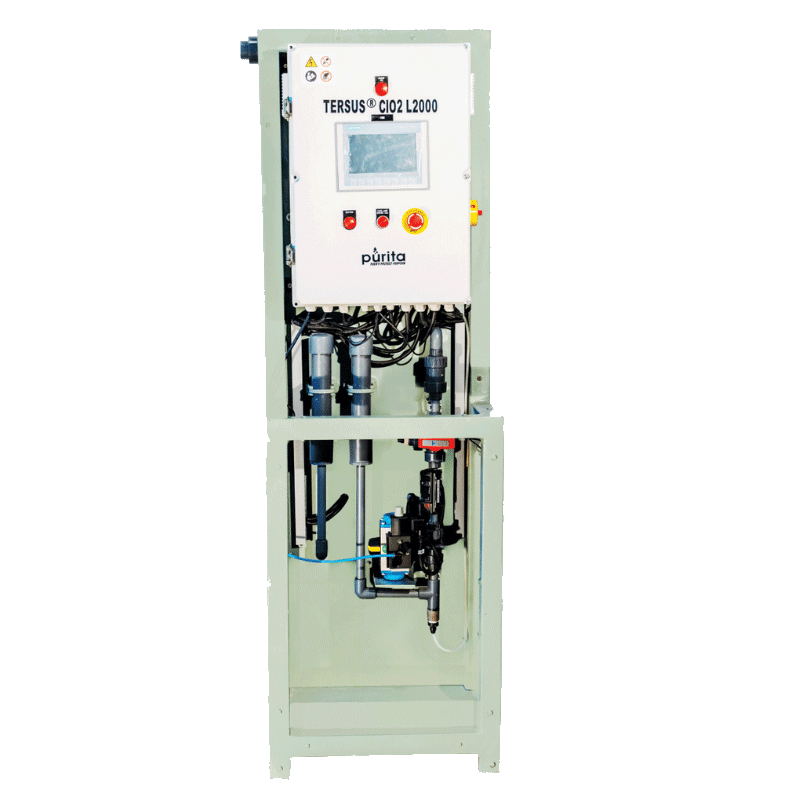

| External Dimensions (W x H x D) | 600 x 1800 x 600mm |

| Power Supply | 230V, 50Hz |

| Protection Max | 6A Power 0.2kVA |

| Display | 7” Touch Screen HMI |

These systems are available with following precursor feeding options

- 24-31% Sodium Chlorite [NaClO2] & 30-33% Hydrochloric Acid [HCl] and

- CLOMAX 4105 Sodium Chlorate based [NaClO3+] & 30-33% Hydrochloric Acid [Hcl] After generation, ClO2 enriched solution is fed into point of use / injection point inline dosing / tank / sump etc., as per dosing requirement

Applications

- Cooling Tower [CW] Water Disinfection

- Sea Water Once-through Cooling Water Disinfection

- Sea Water Intake Water for Desalination Plants

- Potable Water Disinfection for Desalinated Water [Bromate-Free] as per WHO Guidelines

- Pulp & Paper Mills for a Bleach Application

- Municipal Drinking Water Treatment Plants [WTP]

- Centralized Effluent Treatment Plants [ETP]

- Steel, Chemical & Mining Plants for Water Disinfection

- Electronics, Semi-conductor and Solar Cell Manufacturing Plant

TERSUS® “L” Series systems are offered in following configuration

- LX Series: > 0.5 Kg/h to < 2 Kg/h and higher

- LY Series: > 2 Kg/h to < 10 Kg/h and higher

- LZ Series: > 10 Kg/h to 120 Kg/h and higher